What’s The Best Gate Automation System For You?

Pick The Best Gate Automation System For Your Unique Needs

If you want to understand how to select the best gate automation system for you, this article covers everything you need to know.

It explains how gate automation works, how electric gate motors operate and what the differences between the main gate automation systems are.

How do automatic gates work and why are they better than manual gates? Well, to move manual gates, you push or pull them open or closed. That’s hard work. Manual gates often end up left open because it’s a pain to move them yourself every time you come home or go out.

Gate automation systems operate your gates automatically at the touch of a button. This means that your your gates are normally closed for security and privacy. You never need to get out of your car in the rain to open and close them again. Instead, your new electric gate openers operate your gates for you. But how do you know what’s right for your unique needs?

At Electric Gate Repair London, we give customers reliable and up to date information and advice about all aspects of electric gate systems.

When you know more about electric gates you have the right information for when you talk to a gate installer.

What Do Different Types Of Gate Automation Include?

All types of gate automation system include these basic elements:

- A gate motor that’s either an electric motor or hydraulic pump to move each gate leaf

- Electronic control system

- Safety photocells

- Remote controls for opening and closing the gates.

Possible extras include:

- Manual release systems let you manually opens your driveway gates if you have power failure or an electric gate motor breakdown

- Flashing lights warn that your gates are about to start moving or are moving

- Safety edges detect contact with something when the gates are moving

- A loop cable system embedded in the driveway. This detects moving vehicles and operates the gates

- Access control systems with intercoms and or keypads

- 180 degree gate opener system.

An installer mounts each electric gate opener on the gate pillar, wall, pier or post. These connect to the gate in different ways depending on the type of electric gate motor you choose.

There are essentially three types of swing gate motors for automatic gates. These are articulated arm gate motors, ram or linear screw gate motors and underground gate motors.

Each of these types of electric gate motor has advantages and disadvantages.

Read more about electric gate kits here.

What Are The Different Types Of Electric Gate Motors?

SWING GATE AUTOMATION

Articulated Arm Gate Operators

How do automatic gates with articulated arm motors work?

An articulated arm electric gate opener uses a two-part arm with an ‘elbow’ joint to connect the motor to the gate. This arm extends from the gate motor housing so you need room for it to move as the driveway gate opens and closes.

Articulated arm electric gate openers are easier to install than other types thanks to the geometry of the arm system. They can be slightly more expensive than other gate motors but they open and close automated gates quickly.

Many homeowners like discrete gate automation systems and installed articulated arm motors are quite obvious. However, the control panel is built into one of the motors in many of them. Also, because these motors for automatic gates mount onto the inside of gates they’re not seem from the outside of closed gates.

In brief:

- In a power cut or if a motor fails, you can release most articulated arm motors from outside the gate with an optional cable release system

- All articulated arm gate operators are either 230Vac or 24Vdc electric gate motors

- All 24V and some 230V versions have obstacle detection. This means that the gates stop moving and some even reverse when they touch something as they move

- Articulated arm gate automation systems are often the best choice where each electric gate opener is mounted on a large gate pier or pillar.

Ram And Linear Screw Automatic Gate Openers

Ram gate motors and linear screw gate openers are the best gate automation solution where price is important. Their simpler design and operation makes them a cost cost-effective solution compared to other types of electric gate motor.

In brief:

- Ram gate automation motors push and pull a piston mounted on the gate

- Linear screw electric motors for gates use an electric motor to rotate the gate mounting bracket along a threaded shaft

- Both types of electric gate motors are slim and don’t need a lot of space to operate in. However, this advantage does mean that they must be carefully aligned during installation

- Manual release systems only operate from inside the driveway gate

- A ram or linear screw type of motor attaches to the gate at one end and the gate pillar or post at the other end

- Ram motors use hydraulic pumps or electric motors for automatic gate operation but all require a separate control box

- As with articulated arm motors, obstacle detection is available for safer operation

- Additionally, heavy duty versions of these motors move larger gates up to 7m long.

Underground Gate Openers

Many UK home owners choose underground gate automation motors because they are very discrete. This is because each underground gate opener hides under the hinge end of each swing gate.

But how do automatic gates work when hidden underground motors open and close them?

The installer digs a carefully positioned hole for each underground gate opener. Each pit must have good drainage to prevent the motors from sitting in water, or they fail.

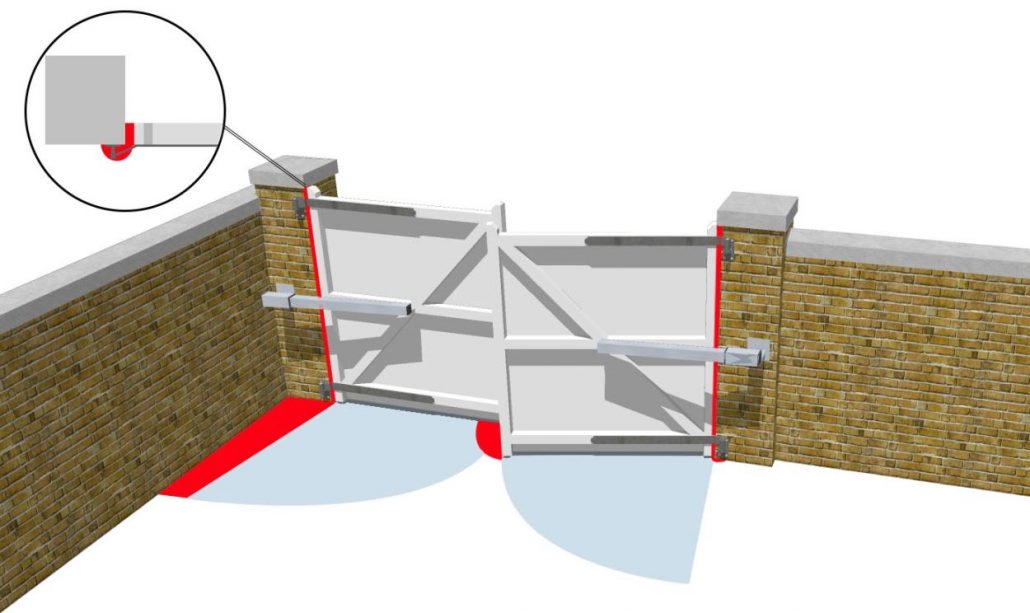

180 Degree Opening

Underground electric gate motors don’t need a lot of space to operate in. They can be installed inside or behind the gate pillars. However, they are usually only installed behind gate pillars when the gates open more than 90 degrees. This ensures that the post or pillar doesn’t stop the gates opening fully. A 180 degree gate opener opens your gates wider than 90 degrees. This is an optional chain drive system used on driveways that bend round behind the gate pillars. If the gate only opens to 90 degrees, it blocks part of the driveway. But a 180 degree gate opener system keeps going past 90 degrees so the gate clears the driveway when open.

In brief:

- Underground gate automation is usually the most expensive solution

- Underground gate motors are completely hidden

- It is possible for the most powerful underground gate opener to open and close a swing gate up to 5m long

- Underground motors for automatic gates can be manually released from outside the gate

- Underground gate motors are either hydraulic or electromechanical

- You need a separate control box

- There are 230Vac and 24Vdc versions with obstacle detection

- A professional electric gate engineers should always install underground gate systems

- Underground gate automation is the best style for you if you want a discrete, almost invisible electric gate motor installation and you have the budget for this more expensive option.

SLIDING GATE AUTOMATION

A sliding gate moves across the opening of your driveway along a track. A single electric gate opener sits on one side of the drive entrance and opens and closes the gate. The motor is positioned so that a cog on the motor’s output shaft meshes with a toothed rack fixed to the inside of the gate. Therefore, as the electric gate motor turns, the cog rotates in the rack and draws the gate along.

A sliding gate opens along a length of straight gate track that is more than twice the width of the driveway. This starts at the pillar or gate post on one side of the opening. It crosses the drive entrance and finishes beyond the opposite pillar. The track is long enough so that the gate slides completely clear of the drive entrance.

In brief:

- Sliding gate automation systems usually only have one gate

- The sliding gate is slightly wider than the width of your driveway entrance

- It slides to one side of the drive opening on wheels that run along a track.

Are Sliding Gates The Best Choice?

Sliding gates are ideal where there isn’t enough space for swing gates to open into the driveway. For example, if the driveway bends, you park cars near the gates, or trees or the house are too close, swing gates will hit them as they swing open.

Additionally, sliding gates are the perfect alternative to swing gates where a driveway runs uphill onto your property. When swing gates open, they hit a rising driveway.

However, you shouldn’t have sliding gates where the driveway slopes across the entrance. In this case, the gate slides uphill one way and downhill in the opposite direction. Gravity pulls it downhill and resists its movement uphill, so the sliding electric gate opener is under extra stress.

If you have a short driveway, you have a lot of cars parked on it or it curves or rises towards the house, sliding gate automation systems might be the best choice for you.

Electric Gate Safety

How Do Automatic Gates Work Safely?

Safety is a vital part of the automation of gates. Electric motors for gates move large, often heavy gates, sometimes against strong winds. Consequently it’s vital to carry out a safety assessment that determines what safety devices need to be incorporated into the electric gate system.

Safety photocells provide a beam of invisible light. Break this beam and the electric gate motors stop the gate moving.

Installers position photocells to protect the area the gates move through as they open and close. Therefore, anyone entering this zone breaks the beam which stops the gates.

Safety edges are installed on the ends of gates and where gates move closer to solid objects like walls and gate posts. Any contact with the safety edge pushes electrical contacts together and the electric gate stops. While safety edges are effective, they only stop the gates moving when they hit something.

Gate Safety Audits

The best gate automation system installers carry out an initial safety audit that identifies the safety issues and provides ways to significantly reduce the risks.

They base this on where they will install the electric gate system and how you will use your electric gates. They also assess how they affect safety when they include additional features such as 180 degree gate opener systems. This is because each additional component creates different safety issues.

Final Thoughts

There’s a lot you can learn about electric gates. For instance, underground electric motors for gates are strong because they move the gates from as close to the hinge as it is possible to get. This means that they use the least leverage available. Consequently, they are stronger than other gate motors which move driveway gates from points much further from the hinge and benefit from leverage.

Here are a few brief points to finish with:

- Manual release systems partially disconnect a gate from its electric gate opener so the gate can be moved by hand

- Loop detectors use a loop of special cable buried in the drive. Drive a vehicle over the loop and it generates a signal that causes the gate to open or close as required

- Before you decide to let them through your automated gate, you can talk to and even see your visitor from your home with an intercom

- You open and close gates at the push of a button with gate remotes or transmitters

- Gate automation stops you getting wet in the rain. It keeps your gates shut for privacy and security when you’re in or out

- Motors for automatic gates complete a cycle in a few seconds and create a great first impression for visitors.

Electric gates are wonderful but choosing the right gates and gate automation system isn’t straightforward. We hope that the information in this article gives you a greater understanding of what an electric gate opener does and what you need to know to make a wise choice.

Now, talking to a good gate installation professional is invaluable.